1.Mechanics le Ho robeha ha Mokhathala:

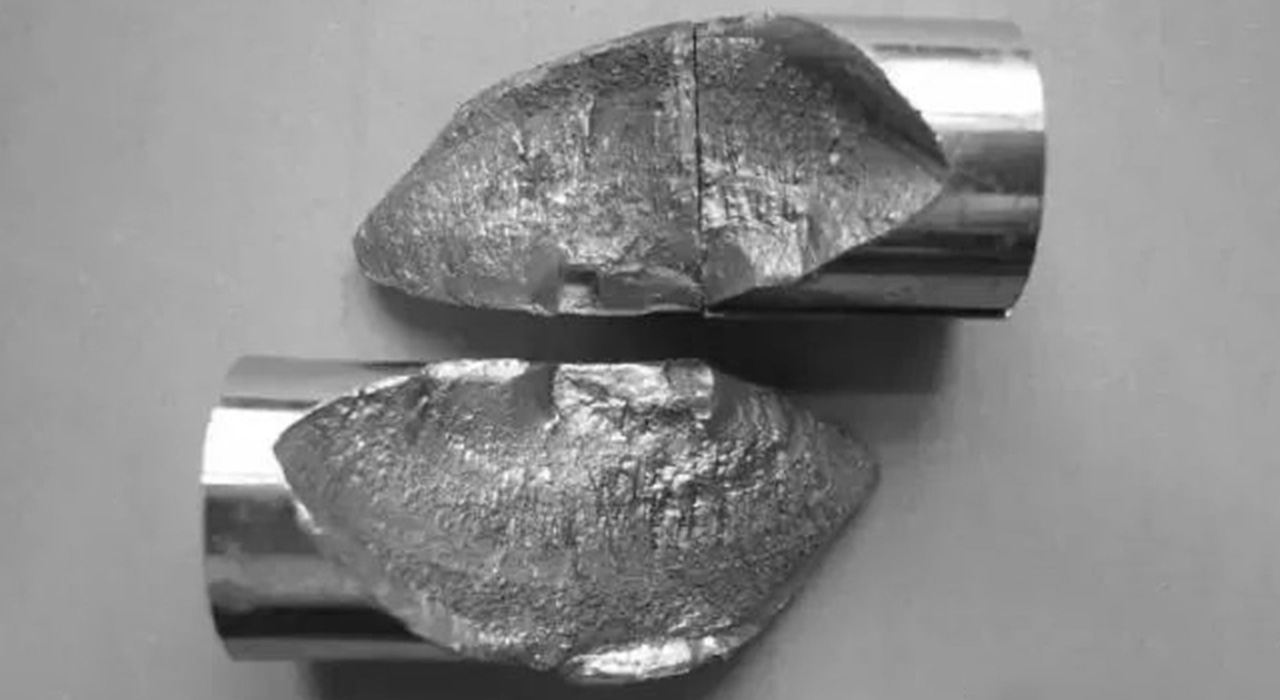

● Teko ea ts'ebetso ea tšepe e tloaelehileng (-196℃--1000℃, tensile, compression, torsion, impact, hardness, elastic modulus);

●Tlhahlobo ea tšepe ea mokhathala le ho robeha ha ho robeha (-196℃--1000℃, mokhathala o phahameng oa axial / low cycle, mokhathala o pota-potileng, sekhahla sa khōlo ea crack, ho tiea ha fracture, joalo-joalo);

● Teko ea CTOD ea sekepe le tšepe ea leoatle;Thempereichara e tlase haholo, ntlha e kholo e teteaneng e peperana

● Metal durability le mocheso o phahameng creep tshebetso liteko;

● Teko ea ts'ebetso ea lisebelisoa tse se nang tšepe le tse kopantsoeng;

2.Rail Transit:

Ho arabela litlhoko tsa indasteri ea lipalangoang tsa literene bakeng sa boima bo bobebe, matla a phahameng, ho itšehla thajana le phokotso ea ho sisinyeha, polokeho le ts'ireletso ea tikoloho, tlhahlobo ea ts'epo ea likoloi tsa terene le thepa ea kaho ea seporo ea etsoa, 'me tataiso ea ts'ebetso le tšehetso ea tekheniki li fanoa. bakeng sa khetho ea lisebelisoa le lisebelisoa tsa boenjiniere.Lintlha tse ka sehloohong tsa tšebeletso ke:

● Tlhahlobo e felletseng ea ts'ebetso ea lipoleiti tsa alloy alloy ea matla a phahameng le liprofaele tsa likoloi tsa terene;

● Tlhahlobo ea lintho tse bonahalang ea likarolo tsa mantlha tse kang bogi, li-gearbox le mabili a lihlopha tsa likoloi tsa terene;

● Teko ea ho hanyetsa ho bola le mokhathala oa li-brackets tsa 'mele oa terene ea koloi le likarolo tse ling;

● Matla a matla le a static le teko ea ho hanyetsa kutu ea pina ea vibration damping fastener;

● Teko ea nako e telele ea liphahlo tsa ho itšehla thajana tsa vibration le li-relastic pads tsa bethe ea pina;

● Teko ea matla a ho hula le mokhathala oa li-fasteners bakeng sa kaho ea pina;

● Teko ea tšebetso ea mokhathala oa likarolo tsa kotopo ea pina.

● Teko ea mokhathala oa liporo tsa terene le lirobatsi tsa maiketsetso;

● Tekolo ea polokeho ea likarolo tse jereng thepa ea marokho a terene;

3. Matla a Motlakase:

Ka lebaka la tšusumetso ea mecha ea phatlalatso ea lik'hemik'hale tsa petrochemical le mashala holim'a ho senyeha ha lisebelisoa, lipatlisiso tsa marang-rang li ka etsoa ho fana ka tharollo ea boleng bakeng sa ts'ebetso e sireletsehileng ea lisebelisoa.Lintlha tse ka sehloohong tsa tšebeletso ke:

● Patlisiso ea ho bola (tekanyo ea botenya, tlhahlobo ea sekala, tlhahlobo ea bofokoli, ho tsebahatsa thepa, joalo-joalo);

● Etsa litlhahiso tsa tokiso ea ho thibela ho bola le ho lekola ho bola;

● Tlhahlobo ea ho hloleha le ho tsebahatsa melato ea kotsi;

● Tlhahlobo ea polokeho le tlhahlobo ea bophelo ea likarolo tsa khatello.

4. Boenjiniere ba Likepe le Leoatle:

Joalo ka "Setsi sa Teko sa Tekolo ea Sekepe sa Sekepe" se lumelletsoeng ke CCS, se ka etsa liteko le netefatso ea ts'ebetso ea lisebelisoa le likarolo bakeng sa tlhahiso ea likepe le matla a moea a tsoang kantle ho naha, nts'etsopele ea oli le khase e kantle ho naha, sethala sa ho cheka kantle ho naha le lisebelisoa tse ling.Lintlha tse ka sehloohong tsa tšebeletso ke:

● Tlhahlobo ea thepa ea sekepe le ho netefatsa ka sekepeng;

● Tlhahlobo ea ts'ebetso ea thepa e khethehileng ea likepe (sepalangoang sa oli e tala, sekepe sa CNG, sekepe sa LNG);

● Tekanyo ea botenya ba sekepe sa sekepe le tlhahlobo ea sekoli;

● Tlhahlobo ea matla (kotulo le ho se tsitse) le tlhahlobo ea mokhathala oa likarolo tsa sebopeho sa hull;

● Ho tsebahatsa kotsi ea likarolo tse tloaelehileng tsa sekepe (motlakase oa matla, tsamaiso ea mooring, tsamaiso ea liphaephe);

● Tekolo ea ts'epo ea sebopeho sa boenjiniere ba kantle ho naha;

● Tlhahlobo ea ts'ebetso ea ho koahela;

● Tlhahlobo, tlhahlobo ea mehlala le tlhahlobo ea liphello tsa lisebelisoa tse kotsi likepeng tse tsamaeang leoatleng.

5. Teko ea Ts'ebetso ea Corrosion:

E sebelisoa haholo ho bona tlhahlobo ea thepa ea ts'ebetso ea ts'enyo ea lik'hemik'hale kapa tsa 'mele (kapa tsa mochini) tse bakoang ke ho sebelisana ha lisebelisoa tsa tšepe le tse seng tsa tšepe le tikoloho, e le ho utloisisa litšobotsi tsa sistimi ea kutu e entsoeng ke thepa. le tikoloho, le ho utloisisa mokhoa oa ho senya.Laola ts'ebetso ea kutu ka katleho.

● corrosion ea tšepe e sa hloekang ka har'a granular, kutu ea sekoti le maphahlo

● Exfoliation corrosion le intergranular corrosion ea motsoako oa aluminium

● Teko e potlakisang ea ho senya ka tlung e etsisang tikoloho ea leoatle (ho qoelisoa ka ho feletseng, ho qoelisoa, ho fafatsa letsoai, galvanic corrosion, ho qoelisoa ka potlako, joalo-joalo);

● Teko ea ts'ebetso ea electrochemical ea lisebelisoa kapa likarolo;

● Teko ea ts'ebetso ea electrochemical ea anode ea sehlabelo, anode e thusang le electrode ea boitsebiso;

● Khatello ea sulfide e bakang kutu le mokhathala;

● Tekanyetso ea ts'ebetso le thekenoloji ea tlhahlobo ea lisebelisoa tsa tšepe le tse kopantsoeng;

● Tekolo ea ts'ebetso ea khoholeho tlas'a tikoloho e etsisitsoeng ea botebo ba leoatle;

● Teko ea ho lemoha ho bola ha microbiological;

● Lipatlisiso mabapi le boitšoaro ba ho hōla ha crack tikolohong ea electrochemical;

● Teko ea ketsiso ea rotor scour e phahameng, e mahareng le e tlase ea lebelo le tlase

● Teko ea ketsiso ea lipeipi

● Teko ea ketsiso ea ho qoelisoa ha metsi ka nako e itseng

● Sefafatsi sa metsi a leoatle + ho pepeseha ha sepakapaka ho potlakisa teko

6. Sepakapaka:

Ho kopanya ts'ebeliso ea li-alloys tsa aluminium tse matla a phahameng, li-alloys tsa titanium le lisebelisoa tse kopaneng likarolong tsa bohlokoa joalo ka lienjine tsa aero, lipoleiti le lisebelisoa tsa cabin aluminium alloy, likarolo tsa sefofane, li-fasteners tsa sefofane, lisebelisoa tsa ho lulisa, li-propeller, joalo-joalo. tekolo ya tshebetso le polokeho Lekola.Lintlha tse ka sehloohong tsa tšebeletso ke:

● Teko ea tšebetso ea 'mele le ea lik'hemik'hale;

● Teko ea ts'ebetso ea 'mele le ea lik'hemik'hale tlas'a tikoloho ea tšebeletso e khethehileng (mocheso o tlaase haholo, mocheso o phahameng haholo, ho roala ka lebelo le phahameng, joalo-joalo);

● Teko ea mokhathala le ho tšoarella;

● Tlhahlobo ea ho hlōleha le tlhahlobo ea bophelo.

7. Boenjiniere ba Likoloi:

Hoa khoneha ho etsa tlhahlobo ea ho tšepahala le ho hlahloba boleng bo pharaletseng ba tšepe ea likoloi, lisebelisoa tse se nang tšepe le likarolo tsa tsona.

Lintlha tse ka sehloohong tsa tšebeletso ke:

● Teko ea thepa ea tšepe (tlhahlobo ea ho hloleha, tlhahlobo ea thepa ea mochini, tlhahlobo ea microscopic, tlhahlobo ea metallographic, tlhahlobo ea lilae, tlhahlobo ea kutu, tlhahlobo ea fracture, tlhahlobo ea welding, tlhahlobo e sa senyeheng, joalo-joalo);

● Teko ea kutu le mokhathala.